IEM Cable Sleeving: Materials, Features, and Use in Different Conditions

- By zikman.audio

The outer sleeving of an IEM (In-Ear Monitors) cable plays a crucial role not only in aesthetics but also in durability, flexibility, and ease of use. Different materials have their own advantages and limitations, especially when used in different environments. In this article, we will explore the main types of IEM cable sleeving, their characteristics, and recommendations for usage.

Types of IEM Cable Sleeving

Thermoplastic Elastomer (TPE)

- Features: High elasticity, wear resistance.

- Pros: Handles mechanical stress well, retains its shape.

- Cons: Can become sticky over time, especially in hot climates.

- Recommended Use: Suitable for daily use but not ideal for extreme conditions.

Polyvinyl Chloride (PVC)

- Features: Rigid and inexpensive material.

- Pros: Affordable, durable, easy to clean.

- Cons: Less flexible, can harden in cold temperatures.

- Recommended Use: Good for home and studio use.

Thermoplastic Polyurethane (TPU)

- Features: Resistant to abrasion and tearing.

- Pros: Highly flexible, durable, water-resistant.

- Cons: Can stiffen in low temperatures.

- Recommended Use: Ideal for active lifestyles and outdoor use.

Polyurethane (PU)

- Features: Softer than TPU but less durable.

- Pros: Good tactile feel, flexible, affordable.

- Cons: Deteriorates over time due to moisture and sunlight exposure.

- Recommended Use: Suitable for light to moderate use.

Polyester (PET)

- Features: Lightweight and strong material.

- Pros: Resistant to stretching, durable, moisture-resistant.

- Cons: Less flexible than PU and TPU.

- Recommended Use: Great for travel and daily use.

Nylon

- Features: High strength, used in fabric sleeving.

- Pros: Lightweight, resistant to mechanical damage.

- Cons: Can absorb moisture and get dirty.

- Recommended Use: Best for long-term durability, suitable for cold climates.

Fabric Sleeving

- Features: Uses natural and synthetic fibers.

- Pros: Aesthetic appeal, pleasant feel, extra protection against mechanical damage.

- Cons: Less moisture-resistant, can attract dirt.

- Recommended Use: Best for home or studio applications.

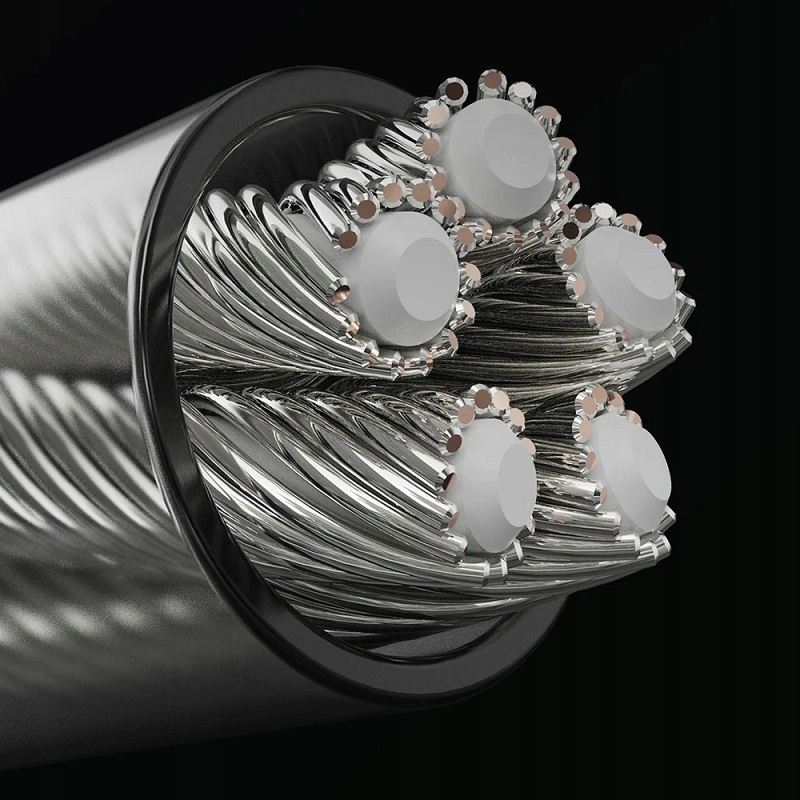

Metal Sleeving

- Features: Uses metallic threads or an aluminum shield.

- Pros: Maximum protection against mechanical damage and electromagnetic interference.

- Cons: Stiffness, increased weight.

- Recommended Use: Suitable for professional and studio environments.

Polyethylene (PE)

- Features: Flexible and resistant to chemicals.

- Pros: Highly resistant to moisture and UV exposure.

- Cons: Less durable than nylon or Kevlar.

- Recommended Use: Great for extreme environmental conditions.

Kevlar Sleeving

- Features: Kevlar fiber, 20 times stronger than steel of the same diameter.

- Pros: Exceptional strength, resistant to heat and chemicals.

- Cons: High cost.

- Recommended Use: Best for athletes and extreme conditions.

Composite Materials

- Features: A combination of different fibers such as silver and fabric.

- Pros: High flexibility, improved operational characteristics.

- Cons: Expensive, complex to manufacture.

- Recommended Use: Ideal for audiophiles and professional musicians.

Best Sleeving Options for Different Use Cases

- For daily use: PET, TPU, and PU provide a balance of durability and flexibility.

- For outdoor and sports use: TPU, Kevlar, or nylon offer maximum protection.

- For studio and professional applications: Metal and fabric sleeving ensure longevity and resistance.

- For audiophiles: Composite materials provide premium quality and comfort.

Conclusion

Choosing the right IEM cable sleeving depends on your needs and environmental conditions. Whether you prioritize flexibility, durability, or aesthetics, the right choice of material ensures the best listening experience with minimal wear and tear. At Zikman, we offer a variety of high-quality sleeved cables designed for every scenario, ensuring you get the best combination of comfort, longevity, and premium sound transmission.

We will answer all your questions about IEM cables and help you determine exactly what you need